2557 Napa Valley Corporate Dr Ste D, Napa, CA, United States of America, 94558

Feeds

Toasting Chemistry: Developing the Barrel Flavor Profile

Of all the controllable organoleptic factors of oak – like species, grain, seasoning, and toasting – toasting is the heavy hitter for flavor impact [to a wine] during maturation. Toasting makes radical changes to the chemical composition of the wood. A skilled cooper can create or destroy flavors during toasting, kind of like a chef adding spices to a dish, to achieve a layered and complex finished barrel.

Toasting is applying varying degrees of heat to a barrel over a specific amount of time. Say it with me, “time” and “temperature” – those are the two key factors. If you remember back to physics class, heat is a form of energy transfer between two objects. Exposing oak to heat energy causes its chemical make-up to change. Heat can be in the form of fire (the traditional method), infrared waves, convection, etc.

As temperature increases, chemical compounds are created and, if the temperature gets high enough, eventually destroyed (see graph below for examples). The same concept applies with exposure to heat over time. Short or long exposure to heat creates its own changes in the oak.

If you read our last Oak 101 article you know that oak is made up of cellulose, hemicellulose, lignin, and tannin. From a flavor perspective, our focus is on the last three elements because they give us the most impact. Let’s apply some heat to these elements and see what flavors we can make.

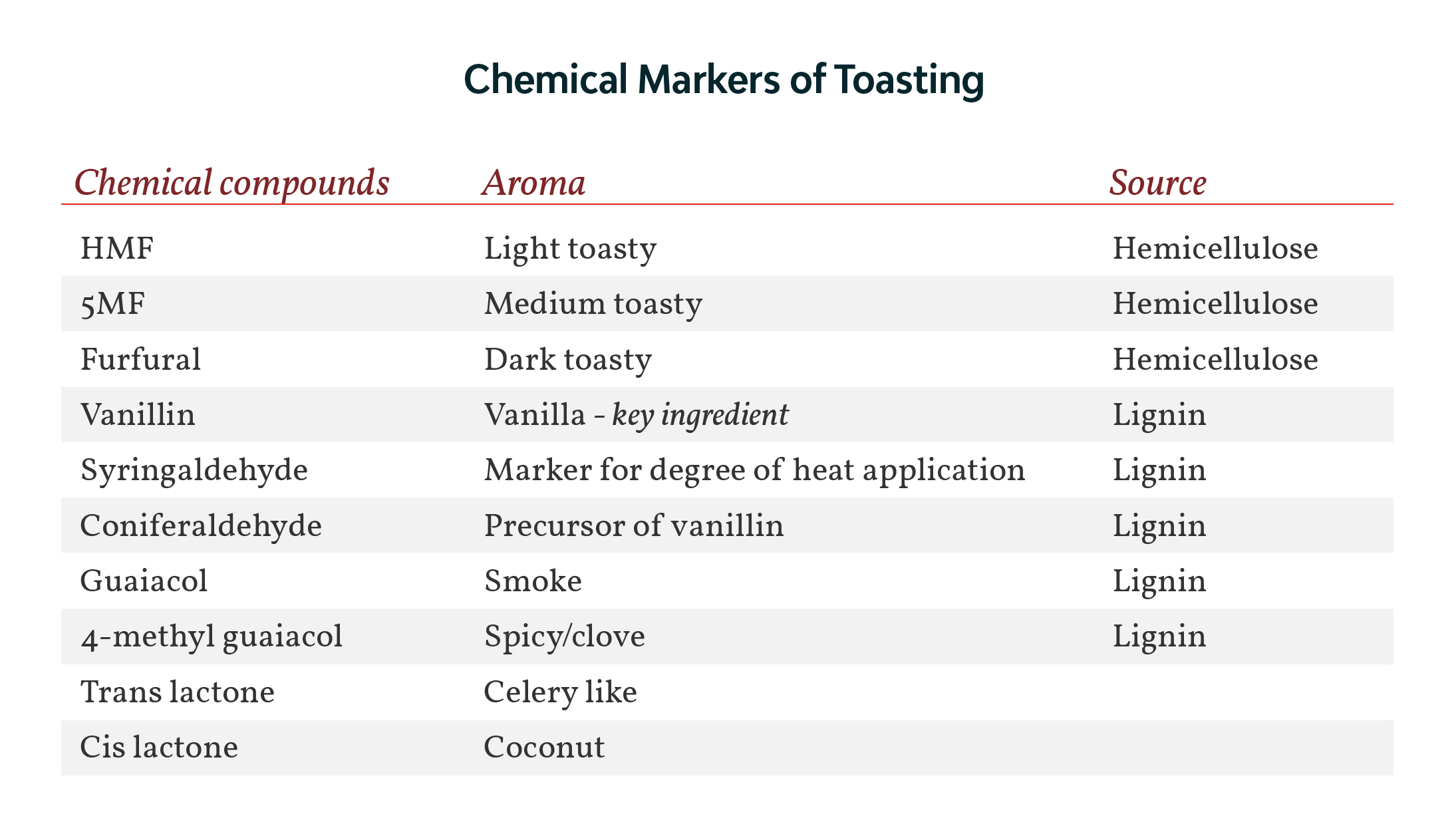

At a certain temperature and heat duration, the hemicellulose in the wood begins to breakdown into simple sugars. These simple sugars then caramelize and become the extractives that provide flavor and body to the wine. For example:

- 5-hydroxymethyl furfural is a chemical marker for light toasty flavors.

- 5-methyl furfural is a chemical marker for sweet, caramel like flavors.

- Furfural is a chemical marker for darker toast flavors like mocha.

Yum. Yum. Yum.

Now let’s take a look at lignin. The lignin in the oak will first breakdown into vanillin and syringaldehyde when toasted – which are desirable characteristics to winemakers. We sometimes like to refer to vanillin as, “catnip for humans”. However, if we apply too much heat, the lignin will breakdown further and create undesirable compounds like guaiacol (which can have a smoky character) or other volatile phenols. It is a delicate balance.

Bottom line, flavor and aroma compounds are created during toasting. Understanding this process is the key to creating barrels with specific flavors. Controlling this process through our proprietary technology, which we call Barrel Profiling, is the key to our consistency.

A note on toasting from World Cooperage Account Manager, and scientist, Glenn Jeffries:

“Targeted temperature ramping can be used to create complex flavor in the different layers of the staves that extract at different time intervals and require different aging duration to achieve balance in the wine.”

- A short, hot toast will provide lots of tannin structure and a whisper of smoke that integrates slowly over a long maturation period and leaves elevated but complex fruit with big structure. Great for Bordeaux styles.

- A longer, hotter toast will provide supple tannin and reduce lactone impact but will also impart a hint of char that remains part of the wine profile. Typically used on American oak due to the breakdown of the lactones. Great for Tempranillo, some Zinfandels, and some Cabernets

The graph above shows a few chemical compounds that come from oak. It summarizes the compounds, what aromas or impact they have on the wine, and what the source is in the oak. The question is: How do you toast barrels to create specific flavors and do it consistently? Stay tuned for our next Oak 101 installment on our Barrel Profiling to learn more about this process.

About

Overview

Cooperages 1912 offers a comprehensive collection of premium wine barrel brands: Tonnellerie Quintessence, Tonnellerie Tremeaux, Maison Moussié, TW Boswell, Heinrich Cooperage and World Cooperage. The Cooperages 1912 team consults directly with winemakers to ensure an optimal pairing between wine and barrel.Cooperages 1912 has a rich history in the wine barrel industry. For almost a century, the Boswell family has committed to excellence, innovation and distinctive barrels that define the very best in coopering.

Contact

Contact List

| Title | Name | Phone | Extension | |

|---|---|---|---|---|

| General Manager North America | Elizabeth VanEmst | evanemst@cooperages1912.com | 707-935-3452 | |

| Account Manager | Tim Suter | tsuter@cooperages1912.com | 314-798-1551 | |

| Account Manager | Yuri DeLeon | ydeleon@cooperages1912.com | 707-396-9874 | |

| Account Manager | Karen Prusinowski | kprusinowski@cooperages1912.com | 707-935-3452 | |

| Account Manager | Zach Thompson | zthompson@cooperages1912.com | 707-738-8670 |

Location List

| Locations | Address | State | Country | Zip Code |

|---|---|---|---|---|

| Cooperages 1912 | 2557 Napa Valley Corporate Dr Ste D, Napa | CA | United States of America | 94558 |