19363 Willamette Dr #181, West Linn, OR, United States of America, 97068

Feeds

Loading feeds please wait a moment

About

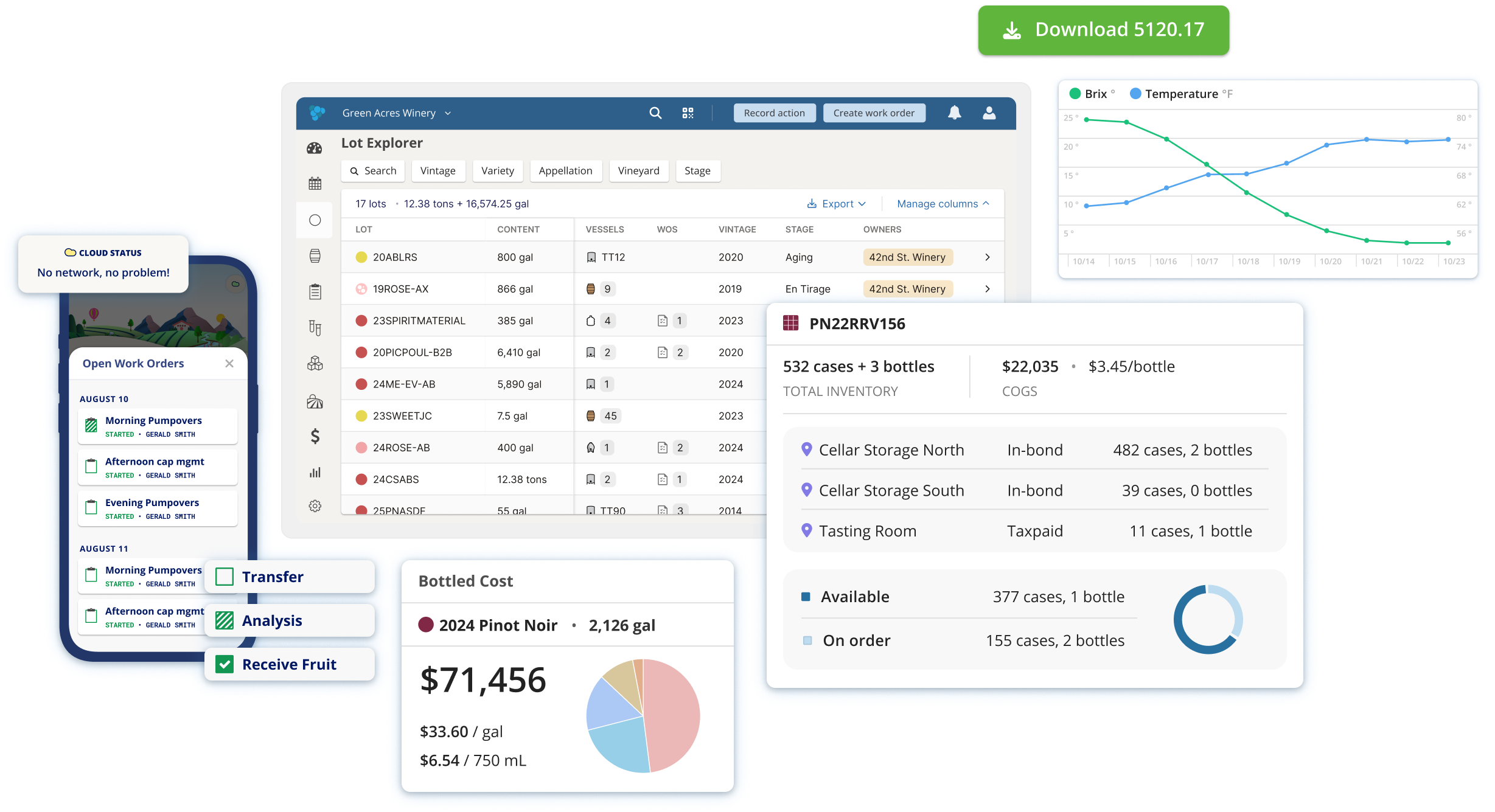

Your Winery Operating System

InnoVint is the leading winery operating system, trusted by more than 2,000 wine brands of every size. Our all-in-one winery operating system brings production, inventory, compliance, and costing into one simple system, giving wineries a single source of truth from vineyard to bottle. With tools tailored to how wineries actually work, InnoVint helps teams stay organized, reduce manual tasks, understand true costs, and make better decisions at every step. Our mission is to help wineries run healthy, resilient, successful businesses.

See InnoVint in Action

Once you get a taste of InnoVint, you’ll get it. Schedule a demo today to learn how your winery can grow, make, and sell wine more efficiently with InnoVint’s winery operating system.

Contact

Contact List

| Title | Name | Phone | Extension | |

|---|---|---|---|---|

| No contacts found | ||||

Location List

| Locations | Address | State | Country | Zip Code |

|---|---|---|---|---|

| InnoVint | 19363 Willamette Dr #181, West Linn | OR | United States of America | 97068 |