East Yanonali Street Suite 15, Santa Barbara, CA, United States of America, 93101

Feeds

Process2wine® : Connected objects

"Connected objects collect information in the field and relay it to Process2Wine production management software where it can be consulted any time and from anywhere."

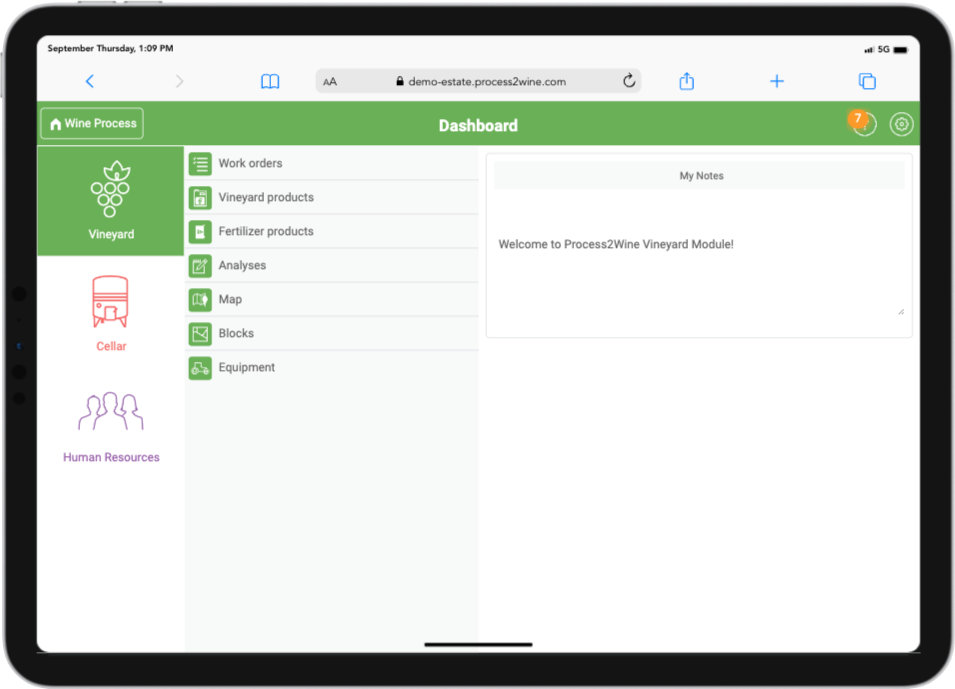

The applications for connected objects are numerous and correspond to very real needs in viticulture and winemaking. With them, a new spectrum of possibilities opens up. Connected objects collect information in the field and relay it to Process2Wine production management software where it can be consulted any time and from anywhere.

At present in the vineyard, the most widespread connected objects are weather stations. They can be supplemented by connected thermometers which follow temperature in real time. Placed at vine level, the temperatures are recorded and displayed on the mapping function in Process2Wine® . This can be useful for triggering frost responses at the correct time and in precise locations. Other types of sensors, connected insect traps, can be installed to automatically record the number of captures. These outdoor sensors are powered by batteries and can be supported by solar panels. The sensors are designed to send data over a distance of several kilometres without recharging the battery over a growing season. They are small enough to be installed within the row of vines.

In the cellar, communicating ambient sensors can measure the humidity and temperature in the rooms where wines are aged and stored. CO2 levels can be monitored during vinification, providing an extra layer of safety in the cellars. When conditions are not optimal, the user is warned, and immediate action can be taken. Sensors connected to bungs can measure the analytical parameters of the wine and transmit them regularly. More generally, water-, electricity- and fuel-use can be monitored and studied to maximise their efficient use. With connected meters it is easy to follow the patterns of consumption. There are limitless ways to connect equipment to generate interesting data.

The main advantage of these technologies is the time it saves; it is no longer necessary to travel to take readings. It is no longer necessary to manually enter data it is done automatically. Additionally, a history of the readings is generated and stored, which allows year-over-year comparisons. The user can be notified when collected values no longer conform to expected values, thanks to an intelligent system that will inform them.

Just as the software’s vineyard map allows you to quickly see your entire operation, using Process2Wine® to map out tasks and assign work teams to prune, spray and pick each block in advance helps you visualize the coming year. As the year unfolds, you can review the observations you and your team recorded on your phones while in the vineyard, study the time and materials expended, and evaluate a myriad of other data. If weather or other factors disrupt the schedule, you can easily revise it on the drag-and-drop calendar, even from your phone.

When deploying a connected-object network, the complete chain of data flow is controlled at a very low operating cost since there is no need to subscribe to a telecom system. The implementation of the network can be gradual and grow as needs evolve.

The data collected can also directly feed decision-support tools such as Exapta®, the new Process2Wine® module for scheduling phytosanitary treatments using daily updates that optimise operations schedules. The accuracy of the collected data makes it possible to work precisely on each of a farm’s blocks while maintaining an extremely rigorous follow-up. More generally, the data collected is available for analysis of the major challenges facing viticulture: production objectives, cost reduction, environmental protection, and consequences of climate change.

https://www.process2wine.us/news/92-process2wine-connected-objects

About

Process2Wine® offers cloud-based vineyard & winery management software allowing you to plan, manage, and record each step of your wine production from the vine to the bottle on an intuitive platform.

Process2Wine® offers cloud-based vineyard & winery management software allowing you to plan, manage, and record each step of your wine production from the vine to the bottle on an intuitive platform.

Along with offices based in France, Canada, and California, Process2Wine has their own research & development department bringing IT professionals and winemakers together to create an efficient software platform to enhance the daily work, reporting, and compliance in the vineyard & cellar.

With a dynamic vineyard & cellar mapping system, Process2Wine allows you to capture real time data and compare between vintages. The software can be accessed with any smart phone or tablet, anytime and from anywhere.

Specializing in estate vineyards and wineries, Process2Wine is built to improve the communication across your organization from the vineyard manager to the winemaker and general manager. Allowing you to enter the world of connected viticulture and winemaking, Process2Wine is a real game changer.

When you sign up to be a partner on a project with Process2Wine, a dedicated account manager will specifically be assigned to your account. You can count on top rated customer service and on-going support, along with important data security with Process2Wine.

Learn more about our software & request a demo on our website:

https://www.process2wine.com/en/

Contact

Contact List

| Title | Name | Phone | Extension | |

|---|---|---|---|---|

| Business Developer North America | Tyson Montano | Tyson.montano@ertus.com | 7606133983 |

Location List

| Locations | Address | State | Country | Zip Code |

|---|---|---|---|---|

| Process2Wine | East Yanonali Street Suite 15, Santa Barbara | CA | United States of America | 93101 |