1900 Summit Tower Blvd, Ste. 1500, Indianapolis, Indiana, United States of America, 46220

Feeds

Join Forces with Us for Specialty Chemical Innovation

Discover how Ravago Chemicals' innovative ingredients can transform your products. 🧪💡 Did you know? As leading specialty chemical distributors, we source from diverse suppliers. Our chemicals enhance industries like CASE, Energy Services, Material Science, Fermented Beverages, Food, Nutraceutical & Pharmaceutical, and Personal Care.

Visit us at na.RavagoChemicals.com to learn more.

Ravago at WIN Expo

Not all yeasts are created equal and seltzer fermentations are very different than beer or wine fermentations.

Not Just A Wine Yeast Anymore

In this blog article, learn how yeasts developed for wine and champagne production can contribute to great seltzer production

Discuss Your Fermentation Needs at Unified

Next week is the 2023 Unified Wine & Grape Symposium! We are excited to see you! Come visit our sales team at booth 442 to find out what we offer and how we can help you!

yeast winemaking ingredients Unified Wine & Grape Symposium fermentation

The History of Yeast (part 1)

In the introductory blog in the Wine Series, we took a look at why it is important to rehydrate yeast properly. In the future, we will talk about and compare and contrast specific strains of yeast. But before we get into what the differences are between specific yeasts, we should take a look at how the yeasts used in winemaking came to be what they are today.

In the introductory blog in the Wine Series, we took a look at why it is important to rehydrate yeast properly. In the future, we will talk about and compare and contrast specific strains of yeast. But before we get into what the differences are between specific yeasts, we should take a look at how the yeasts used in winemaking came to be what they are today.

Yeast is not new. It didn’t get invented. The fungus occurs naturally and has always been here with us and has changed along with us humans.

Sometime, possibly around 5,000 years ago, humans realized yeast could be a tool and domesticated for our own purposes – whether that’s making bread or alcohol. In breadmaking, the yeast gives the bread CO2 bubbles to make the dough rise. Back then, people didn’t know about potassium bitartrate or other chemical means of making dough rise, so all bread was naturally fermented by using yeast and/or sourdough bacteria.

In nature, yeast divides and makes a clone of itself – an exact copy of itself or at least it tries to. Same as with humans, when yeast makes copies of their DNA there are mistakes or mutations that happen in the process. Through time and the accumulation of these mutations, yeast has evolved. As a result, a naturally occurring yeast that exists in a certain geographic area will be different from a naturally occurring yeast in a different geographic area.

Now let’s talk about how humans, specifically winemakers for the last few centuries or millennia, influenced this process in a basic way. What happens is winemakers end up with a feedback loop where a winery took the grapes, crushed them, and lets them ferment. Then when the fermentation was done, the yeast shut down and put itself into suspended fermentation waiting for the next opportunity to live. As part of the winemaking clarification process, the winemaker lets the wine settle. The live yeast, dead yeast, and other particles settle to the bottom due to gravity and the clear wine remains at the top. The winemaker then drains the clear desirable wine off of the “lees” or all of the heavy particles. What does the winemaker do with the lees? They would get thrown back into the vineyard as nutrients for the soil.

The yeast is now back in the vineyard, and the wind blows, and the yeast dries and lays dormant in the soil and on the grapevines. This puts the “natural” yeast used to ferment the wine from one year back into the vineyard to get back on the next years grapes and then ultimately to ferment next year’s wine and on and on it goes. It becomes a feedback loop that selects the yeast that does a good job of fermenting the grapes into wine.

So, geographically, certain regions became famous for their wines for two reasons:

- The grapes grew really well and the winemakers had an easy time making good-tasting wine out of the grapes in the area because the climate was perfect for that grape variety.

- Through the feedback process, they managed to naturally select strains of yeast to make good-tasting wines.

Historical examples of these regional yeast, appellation and terroir combinations come from the “old world” regions like Bordeaux, in France. Whether it was a Red wine blend or white Sauternes wines from Bordeaux, these wines historically are highly regarded and can demand many hundreds to many thousands of dollars per bottle. They evolved their own historical yeast strains through yeast reuse. The same goes for Burgundy and Beaujolais. Germany and Italy also have appellations with historic yeast strains that evolved and were used there. Many of the places that have wine styles named after them have equivalent yeast strains that evolved from the region.

While this process was occurring, science was evolving.

Turn back the clocks to around 1590, when the microscope was invented, then forward to 1680, when yeast was first identified. From there we move to 1857 when it was discovered that yeast was the cause of alcoholic fermentation.

The combination of the scientific method, the invention of the microscope, and the realization that yeasts can be cultured, grown, and selected made it possible to give wine or beer a whole new yeast industry.

From this, a whole yeast industry was born for the making of wine, beer, cider, and bread.

To learn more, or to discover the breadth of RCNA’s yeast catalog, please click here.

Rehydration - Waking Up the Best Way Possible

Maurivin Active Dry Wine Yeast should not be stirred for 15 minutes during the inoculation process. Find out why and when on our blog: https://shop.ravagochem.com/support/s/blog/rehydration-waking-up-the-best-way-possible-MCUUMVKYX2NNCITH6DIMIUAO4LAY

Explore Maurivin AWRI UVAmaX, Used to Lower Volatile Acidity in Wine, Particularly Late Harvest, Dessert-Style Wines

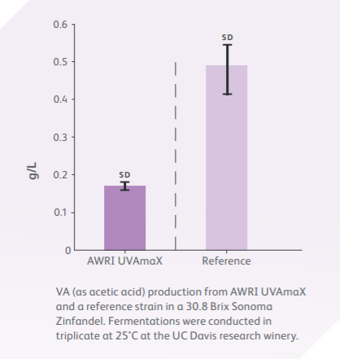

AWRI UVAmaX is a yeast strain that has naturally low production levels of acetic acid (Vinegar) and ethyl acetate (Acetone or nail polish remover). It is also highly alcohol tolerant. Together these attributes make a much better late harvest and dessert style wines. Wines made with this yeast are more pleasant and sweet due to their natural aromas and flavors not being masked by undesirable characteristics.

download technical data sheet

Chardonnay, Merlot, Zinfandel and Semillon

CONTRIBUTION TO WINE

AWRI UVAmaX has the natural capability to reduce the level of volatile acidity in wine. The resultant wine made with this yeast makes it more pleasant due to the decrease in acetic acid (vinegar) and ethyl acetate (nail polish) aromas.

AWRI UVAmaX has the natural capability to reduce the level of volatile acidity in wine. The resultant wine made with this yeast makes it more pleasant due to the decrease in acetic acid (vinegar) and ethyl acetate (nail polish) aromas.

RATE FERMENTATION

AWRI UVAmaX has a short lag phase with a medium to fast fermentation speed at temperatures of 12-26°C (54-79°F).

APPLICATIONS

In winemaking trials in Australia and the USA, AWRI UVAmaX was shown to clearly reduce the volatile acidity by chemical and sensory analysis in Chardonnay, Merlot, Zinfandel and Semillon trials. We recommend using this yeast when there is a desire to reduce volatile acidity levels which can be elevated in dessert, late harvest-style wines; the alcohol tolerance of this yeast makes it suitable for such applications.

Buy here.Buy here.

Winemaking Ingredients on Sale

New Lower Price on Citric Acid. Was $189, now $169. Stock up and save now. Fuel surcharges apply for 1-3 bag purchases.

Get some now here: https://shop.ravagochem.com/Personal-Care/dry-citric-acid

New Winemaking Product!

We are now offering our AB Biotek Mauritan Vini - a blend of tannins which early in fermentation inactivates oxidative enzymes, precipitates grape proteins and preserves endogenous tannins - at just $58.99 per 2.2 LB, including free delivery!

Get some Mauritan Vini right now.

About

Ravago Chemicals represents market-leading specialty chemical and ingredient producers that allow us to deliver creative technical solutions along with the highest level of service to more than 15,000 active customers across more than 24 countries worldwide. We are a family company and place a high value on our long-standing relationships with our suppliers, customers, and our colleagues. In North America, Ravago Chemicals (RCNA) has been providing quality, innovation, and sustainability to the specialty chemical and ingredient markets through its family of companies for more than 50 years.

Contact

Contact List

| Title | Name | Phone | Extension | |

|---|---|---|---|---|

| Segment Manager, Fermented Beverages | Steve Shaffer | sshaffer@ravagochem.com | ||

| Regional Commercial Director | Tinus Els | tinus.els@ravagochem.com | ||

| PNW Account Manager | Martin Lysness | MLysness.com | ||

| Account Manager California North Coast | Mary Beth Pellegrino | marybeth.pellegrino@ravago.com | ||

| ACCOUNT MANAGER, Central Coast CA | Peter Vallis | PVallis@RavagoChem.com | (559) 400-2438 |

Location List

| Locations | Address | State | Country | Zip Code |

|---|---|---|---|---|

| Ravago Chemicals North America | 1900 Summit Tower Blvd, Ste. 1500, Indianapolis | Indiana | United States of America | 46220 |