703 2nd St Ste 445, Santa Rosa, CA, United States of America, 95404

Feeds

.jpg)

WINnovation Award 2023: VinWizard —Delivering Accurate Brix and Temperature Measurements from Inside the Fermentation Tank

The wine industry is constantly faced with new trends, challenges and the pressure to stay ahead of the competition. With that comes the opportunity to innovate.

Each year, Wine Industry Network recognizes five wine industry innovators — not just for their impressive ingenuity or technical advances — but because of how their product and/or service betters the North American wine industry.

By Jeff Siegel

How does a product work successfully for customers as diverse as a multi-national wine brand, a luxury Napa producer and a teaching winery?

How does a product work successfully for customers as diverse as a multi-national wine brand, a luxury Napa producer and a teaching winery?

By giving winemakers insight into the highest and lowest temperatures in the tank, says Kelly Graves, CEO of Sonoma’s VinWizard, whose new Multi-Sensor Probe, or MSP, does just that. And what winery – regardless of size or reason for being – doesn’t want to know that kind of information?

“This way,” Graves says, “winemakers can feel comfortable running the yeast at the higher end of its tolerance zones, generating highly sought after flavors and aromatics without running the risk of a stuck fermentation.”

Success follows success

The MSP follows VinWizard’s Multi-Level Probe, or MLP, which debuted in New Zealand some 10 years ago. The first probe let winemakers determine the temperature of the entire wine tank. Its successor goes one step beyond that.

“Having achieved success with the MLP, it was time to take a stab at addressing one of the biggest opportunities [for advancement] during harvest — providing real-time Brix measurement during fermentation without costing a fortune,” says Graves. “Any solution had to provide a positive return on investment when compared to sending an employee out to the tank front twice daily to pull samples and spin a hydrometer or use any of the existing technology.”

The MSP starts at the top of the tank and runs from top to bottom, so winemakers are able to gather multi-level Brix readings while avoiding the cooling jacket impacts that skew results. In this, the MSP’s placement within the tank has been designed to yield the most accurate temperature and rate of fermentation at the core of the tank, while not interfering with pump over devices and CIP set-ups.

The MSP’s data can be combined with automation platforms from VinWizard or its sister company, Octent Automation. Then, the data can be used to set up various fermentation and winemaking functions. For instance, MSP data can trigger a low volume pump over cycle and tank warming when a Brix rate of change is first detected.

The MSP’s data can be combined with automation platforms from VinWizard or its sister company, Octent Automation. Then, the data can be used to set up various fermentation and winemaking functions. For instance, MSP data can trigger a low volume pump over cycle and tank warming when a Brix rate of change is first detected.

“Wine quality, asset use efficiency and overall winery outcomes will be improved by the proper employment of MSP-provided information,” says Graves. “That’s because the MSP has been designed and sold by a company whose specialty is wine production automation. It’s valuable by itself to have the MSP data; it’s a game changer to link the data with a platform that can actually effect change in the cellar based upon the data the MSP provides.”

Eliminating the guesswork

That’s one of the things that surprises VinWizard customers the most, says Graves.

“The data itself shocks winemakers,” he says. “While an educated guess can estimate the temperature inside the skin cap, there are so many variables that impact the thermodynamics of a fermentation, it is essentially impossible to infer what’s going on inside the tank.” Until now.

In the end, real numbers in real time make all the difference.

About

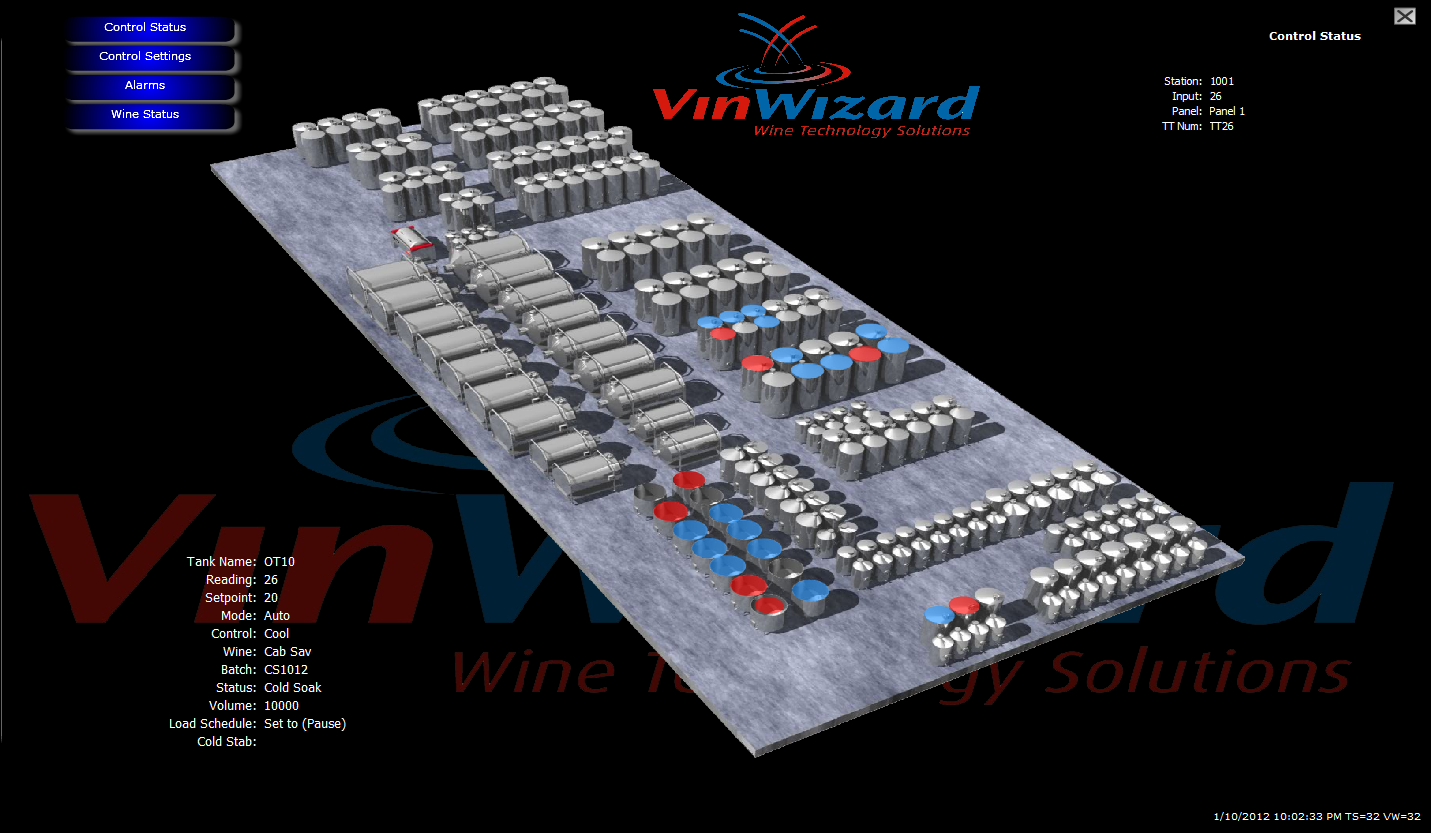

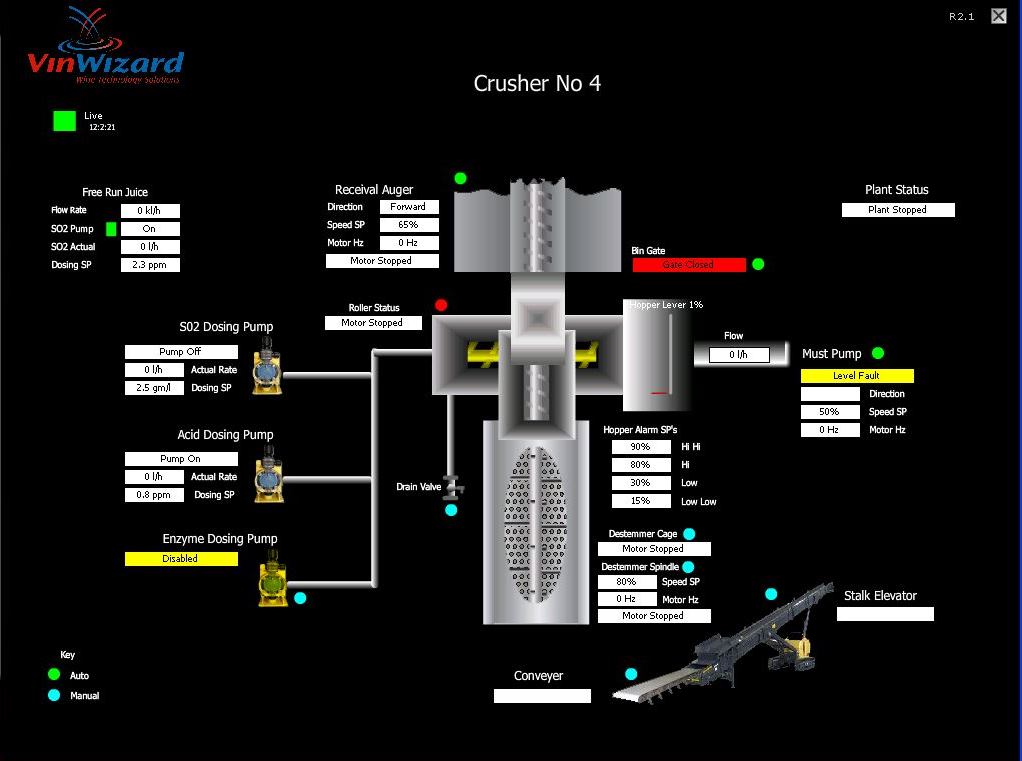

Founded in 1996 VinWizard is established as the default technology for next generation tank control and complete facility integration. Over 200 leading wineries around the world rely on the system to help maximise the potential of fruit entering the winery while reducing power consumption and staff requirements.

Operating a tank control system in isolation is no longer an option for wineries concerned with production cost and wine quality. Through integration with refrigeration plant and application of powerful software logic power savings of up to 50% are readily achievable. Wine is better protected with alarms raised at the source and not when tanks have suffered the impact. Refrigeration resources can be directed to the tanks that most need it and plant can be operated at an appropriate level according to load and power price periods.

Tank control is taken to new levels giving winemakers a greater understanding of what is actually happening inside the tank. Tank temperature control, automated pumpovers, air injection, headspace gassing and agitator control save labor, reduce mistakes and enhance the wine. In-tank sensors deliver on-line monitoring of temperature stratification, brix and redox with data readings triggering temperature changes, pumpovers and agitators. Integration with winery production software allows a seamless bi-directional exchange of data which can trigger temperature profiles in VinWizard and display data where most needed.

VinWizard Temperature Control Introduction

VinWizard Modules, Power and Water

Multi-Level-Probe Introduction

VinWizard Pneumatic Air Valves Introduction

Temperature control with single or multiple sensor options

Temperature control with single or multiple sensor options

Interface to refrigeration plant for control & energy savings

Interface to refrigeration plant for control & energy savings

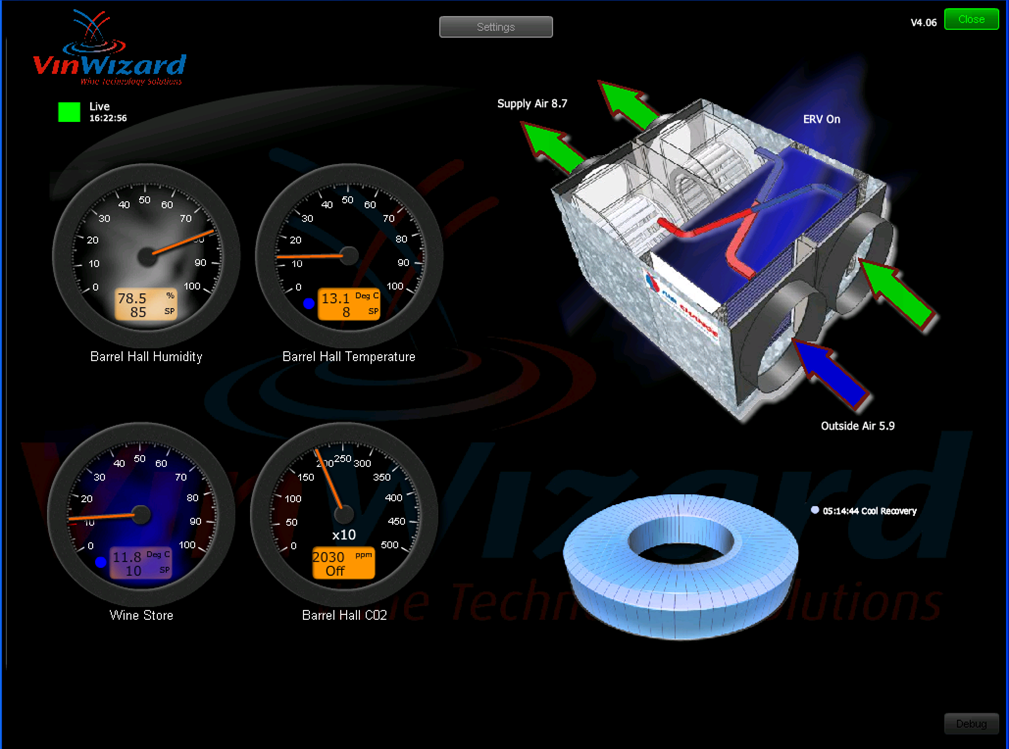

Barrel hall monitoring and control

Barrel hall monitoring and control

Contact

Contact List

| Title | Name | Phone | Extension | |

|---|---|---|---|---|

| Managing Director | Kelly Graves | kelly@vinwizard.us | +1 7202842059 | |

| COO | Robert Richards | bobrichards@vinwizard.us | +64 021731770 |

Location List

| Locations | Address | State | Country | Zip Code |

|---|---|---|---|---|

| Wine Technology Incorporated | 703 2nd St Ste 445, Santa Rosa | CA | United States of America | 95404 |